Touch screen technology is integral to modern electronics, from smartphones to interactive kiosks. At the heart of this technology are advanced materials and processes, particularly conductive coatings. These coatings, which include indium tin oxide (ITO), aluminum-doped zinc oxide (AZO), and transparent metallic films, play a vital role in the functionality of touch screens. They provide the essential electrical conductivity while preserving the transparency necessary for display applications. Let’s delve into the most commonly used conductive coatings and the advanced techniques utilized to apply them.

Common Conductive Coatings

Indium Tin Oxide (ITO): ITO coatings are a staple in touch screen manufacturing, known for their exceptional electrical conductivity and transparency. ITO is predominantly used in capacitive touch screens, where it is applied to glass or PET plastic. This coating enables the screen to detect electrical charges from a user’s touch while maintaining optical clarity. Its durability and moisture resistance make ITO a preferred choice for a wide range of display applications.

Aluminum-Doped Zinc Oxide (AZO): AZO offers an excellent alternative to ITO, providing comparable electrical conductivity and transparency. Many manufacturers favor AZO for its cost-effectiveness and environmental advantages, as zinc and aluminum are more abundant than indium. Moreover, AZO’s flexibility makes it ideal for the increasingly popular flexible and curved touch screens.

Transparent Metallic Coatings and Films: Beyond ITO and AZO, other transparent metallic films are also employed. These may include thin layers of metals such as silver, copper, or gold. While these coatings might not achieve the same transparency as ITO or AZO, they are useful in applications where conductivity is prioritized over optical clarity. For example, in industrial or military displays produced by rugged display manufacturers, a slight reduction in transparency can be tolerated for enhanced performance under harsh conditions.

Magnetron Sputtering vs. Ion-Enhanced (IAD) E-Beam Evaporation

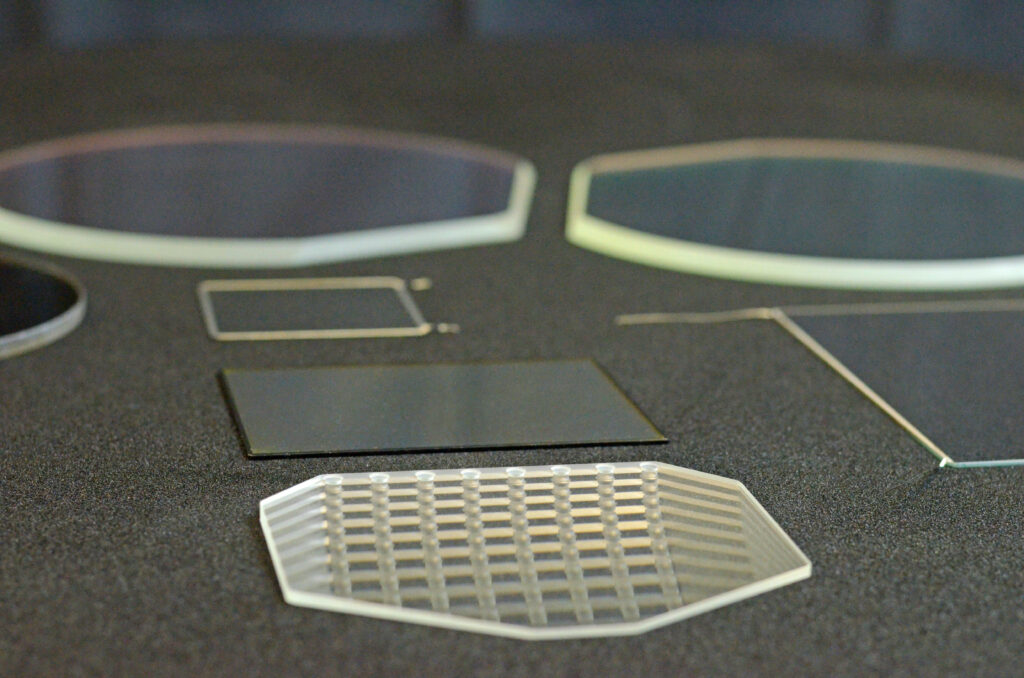

Applying these conductive coatings onto transparent substrates, such as glass or plastic, involves advanced deposition techniques like magnetron sputtering and ion-enhanced (IAD) e-beam evaporation.

Magnetron Sputtering: In this process, a target material (such as ITO or AZO) is bombarded with ions in a vacuum chamber. The impact causes atoms to be ejected from the target material, forming a PVD thin film coating on the substrate. Magnetron sputtering is widely used in touch screen manufacturing due to its precision, ability to create smooth films, and adaptability to various substrates.

Ion-Enhanced (IAD) E-Beam Evaporation: IAD e-beam evaporation is another technique used by touch screen manufacturers to apply conductive coatings. This method involves using an electron beam to heat the target material, causing it to evaporate and deposit onto the substrate. Simultaneously, ionized gas is directed onto the substrate, enhancing the coating’s adhesion and density. This approach offers precise control over the coating’s thickness and composition, making it ideal for producing high-quality thin films with specific optical and electrical properties.

Subcontracting Thin Film Deposition: A Strategic Approach

Due to the complexity and precision involved in applying these coatings, touch screen manufacturers often subcontract the thin film deposition process to specialized providers. This strategy allows manufacturers to focus on other aspects of production while ensuring that the coating process is handled by experts who offer specialized ITO coating services in Pennsylvania and PVD coating service in PA.

Subcontracting also provides flexibility in production. Manufacturers that produce various types of touch screens may require different coatings depending on the application. By partnering with coating service providers, they can ensure that each batch receives the appropriate treatment, whether it’s ITO for capacitive touch screens or AZO for flexible displays.

Display Enhancements and Other Coating Technologies

In addition to conductive coatings, manufacturers often seek other types of LED display enhancements to optimize performance. These enhancements include anti-reflective coatings, polarization films, and filters that manage RGB light distribution. For example, anti-reflective coatings reduce glare and improve visibility in bright environments, while polarization films enhance image contrast and clarity. Such additional coatings are crucial for manufacturers of high-performance displays, including those used in medical devices, automotive dashboards, and industrial control panels.

Manufacturers of optical devices often rely on specialized coatings to meet their products' unique requirements. For instance, coatings for manufacturers of optical devices might include layers that reduce reflection or enhance the contrast and brightness of the display. These coatings are essential for ensuring that displays meet the rigorous standards required across various industries, from consumer electronics to aerospace.

Conductive coatings are the foundation of touch screen technology, and applying them requires precision and expertise. Whether using ITO, AZO, or transparent metallic films, manufacturers must ensure that their coatings achieve the delicate balance between conductivity and transparency. Techniques like magnetron sputtering and ion-enhanced e-beam evaporation are just two of the many methods that guarantee high-quality results. When selecting a coatings provider, it is crucial to partner with experts who understand the nuances of thin film deposition and can deliver top-tier results for your production needs.

Comments on “Types of Conductive Coatings Commonly Used by Touch Screen Manufacturers”